Empire State Building Construction: 410 Days to the Sky

Inside the Empire State Building’s record‑breaking construction: crews, steel, elevators, and the logistics that made a 102‑story miracle.

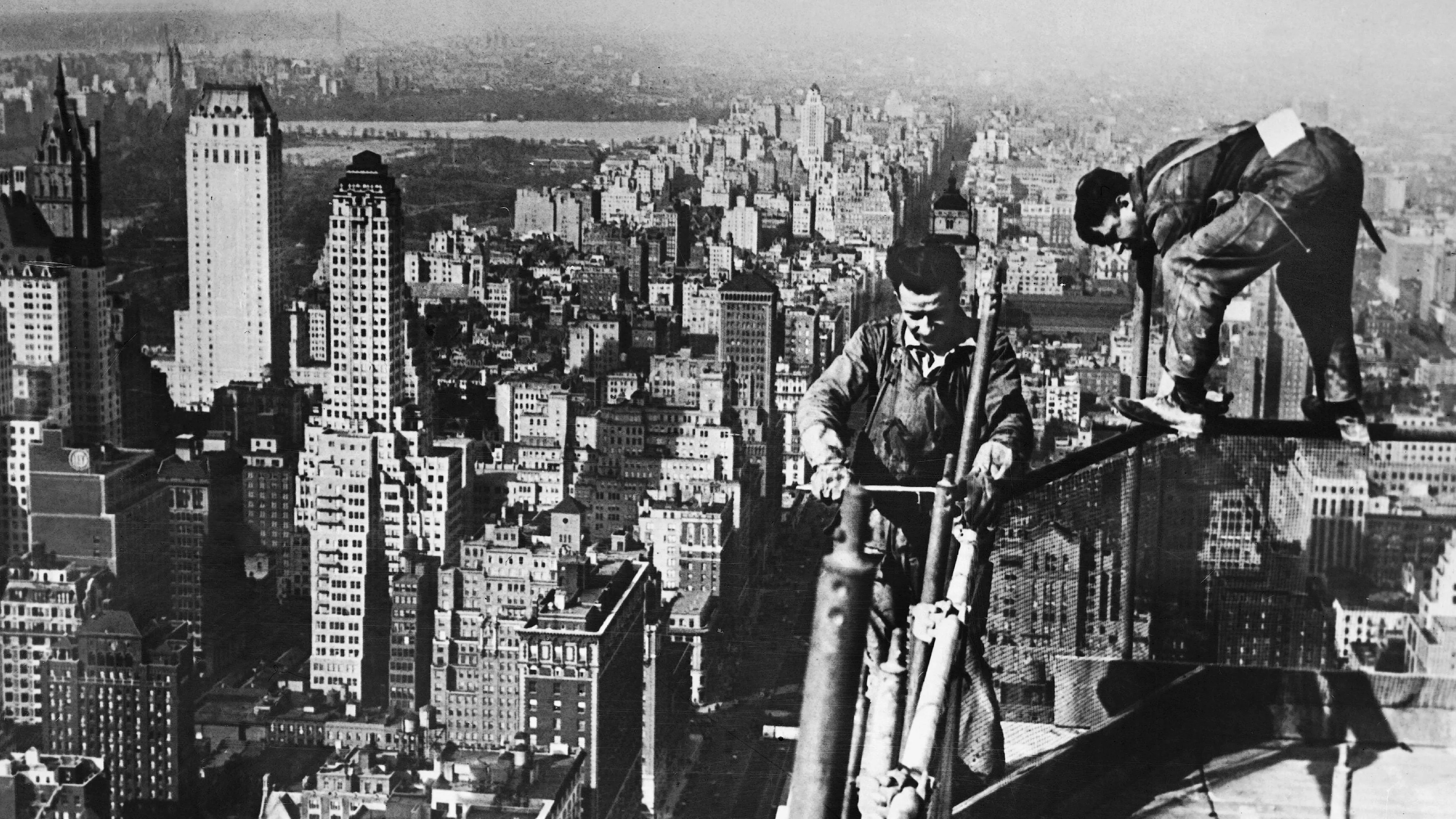

Speed defined ESB’s build: steel frames erected at up to 4.5 floors per week, with precision choreography across deliveries, rivets, and safety protocols of the era. It was not chaos — it was a ballet of cranes, hoists, and human rhythm.

Quick Facts

- Total construction time: ~410 days.

- Peak workforce: ~3,400 workers.

- Steel: ~57,000 tons; 10M bricks; 200,000 cubic feet of stone.

- Average floor progress at peak: 1 story per day (steel skeleton).

| System | Innovation |

|---|---|

| Prefabrication | Steel members arrived ready to rivet |

| Hoists | Material/men moves tuned by shift cadence |

| Scheduling | Daily output boards and micro‑targets |

| Safety | Evolving gear; netting, routines, and spotters |

Crew & Craft

- Mohawk ironworkers: balance, speed, and trust — a legendary high‑steel lineage.

- Riveting teams: heaters, tossers, catchers, buckers — each with a role and rhythm.

- Decking crews: laid floors almost as fast as steel rose.

- Elevator installers: turning vertical shafts into arteries.

Did you know? A tossed hot rivet could arc 50–75 feet — caught in a bucket, then hammered home in seconds.

A Day in Motion

- Dawn deliveries staged on 5th Ave.

- Steel hoisted and pinned; temporary bolts before rivets.

- Rivet fires lit; teams cycle floor to floor.

- Decking and perimeter safety follow the steel.

Logistics at Scale

- Staged deliveries to 5th Avenue; traffic managers orchestrated the curb ballet.

- Prefabricated steel — minimal on‑site fit‑ups; faster erection.

- Daily production targets per crew; micro‑scheduling kept pace.

- Weather windows exploited; wind management dictated task choice.

Safety evolved rapidly, but the height risks were real — the heroism was in routine done right.

Numbers That Tell the Story

| Metric | Peak Rate |

|---|---|

| Steel fastening | 10,000+ rivets/day |

| Concrete | Hundreds of cubic yards/day |

| Elevators | Dozens of installers across multiple shafts |

See the Story

- Photographs of beam walkers, skyline lunches, and winches tell the tale.

- Exhibits on lower floors map the ascent floor‑by‑floor.

- Look for the sequencing diagrams — they make the speed legible.

Bottom Line

ESB’s build was speed with discipline: a city pushing limits and inventing modern project management as it climbed. It’s the template for how the modern metropolis assembled itself.

A szerzőről

NYC Observatory Expert

Azért készítettem ezt az útmutatót, hogy az Empire State Building látogatása egyszerű, tartalmas és tele legyen jó New York‑i tippekkel.

Tags

Comments (0)

Loading comments...